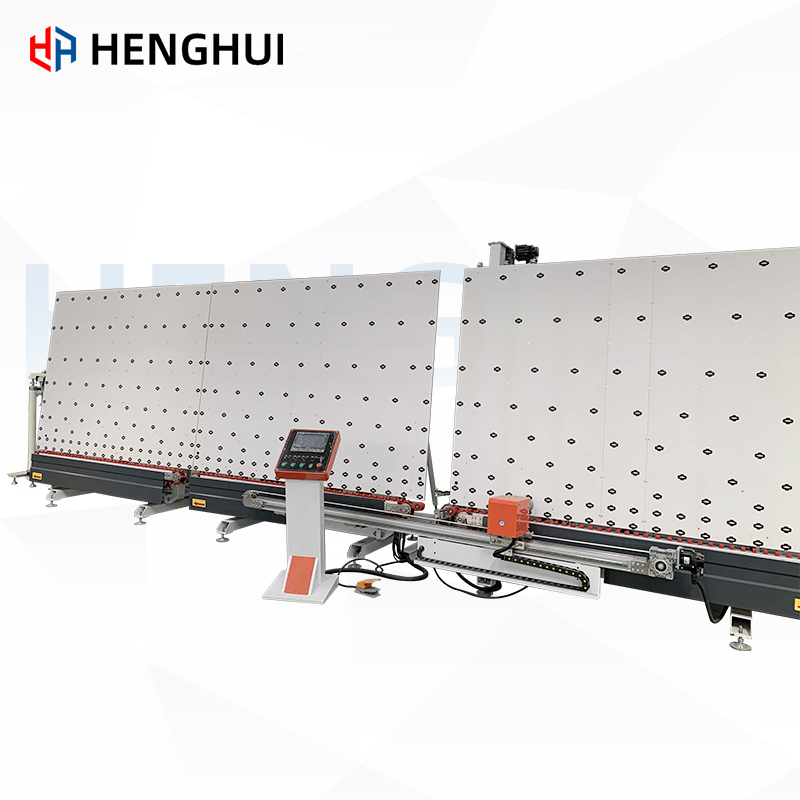

Automated Hot Melt Sealing Robot

Model No.: HH-FJX-2025

Brand: HH

Place of Origin:China

Max Glass Size: 2000*2500 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

1.Introduction of the product

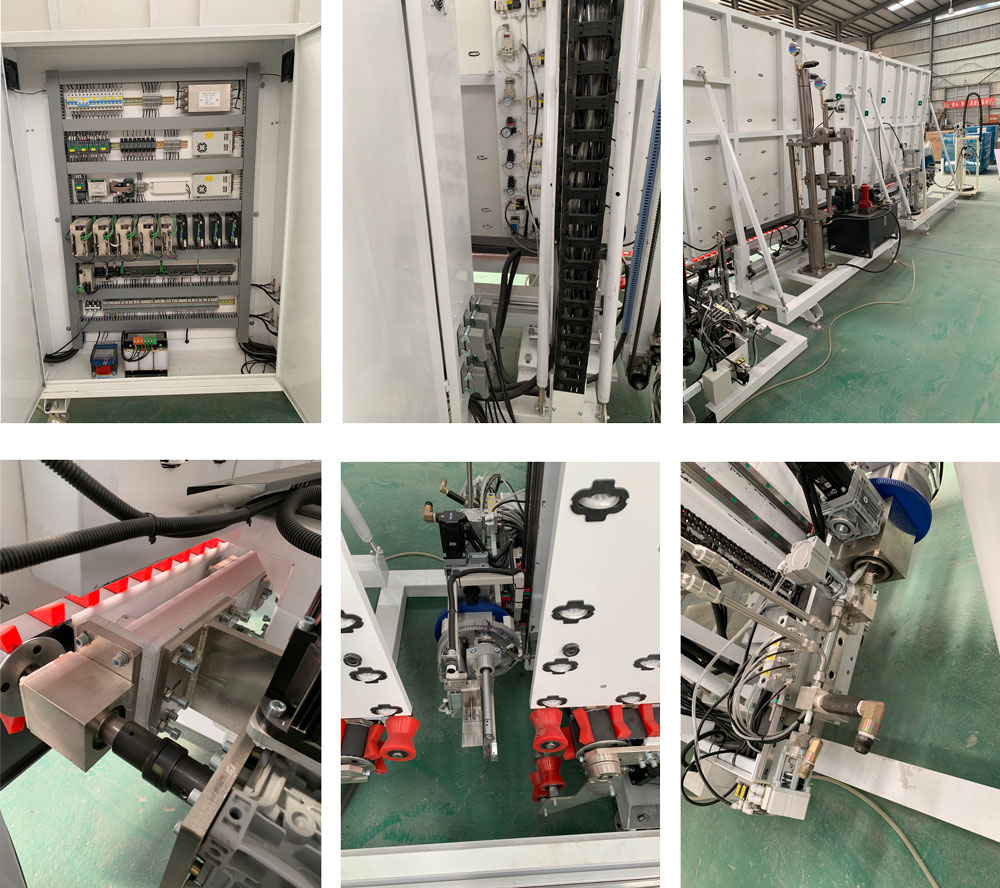

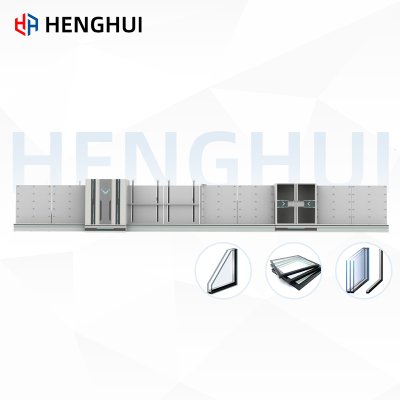

This advanced production line is our company's premium automatic sealing equipment dedicated to the final sealing process in insulating glass production. It includes a feeding section, a discharging section, a glue dispensing system, a suction cup conveying system, a glue supply system, a pressurizing balance system, as well as hydraulic and electrical systems.

2.Product advantages

(1) 9-axis linkage for efficient glass mass production.

(2) User-friendly interface design for easy operation.

(3) Additional section for glass storage to enhance production efficiency.

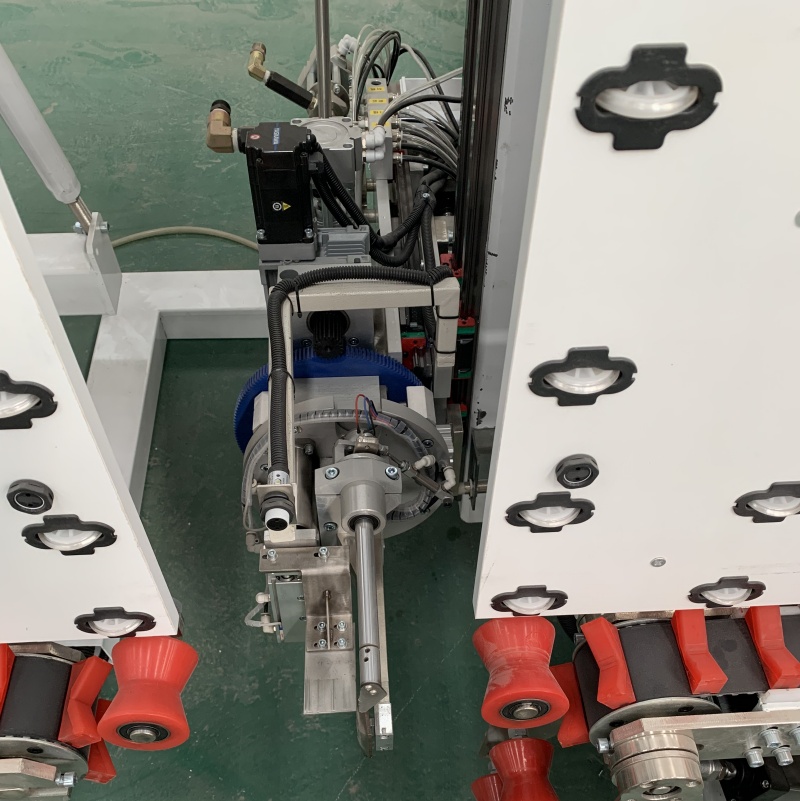

(4) Airline-free glass edges with flat corners, eliminating the need for corner repairs.

(5) Stable performance with a servo control system from a renowned global brand.

(6) Synchronous belt transmission for smooth glass movement and precise positioning.

(7) Unique V transmission system minimizes adhesive issues on the conveyor belt to keep glass edges clean.

(8) Utilization of high-quality parts and components ensures long-term equipment stability and performance.

3. Product parameters are as follows

Model | HH-FJX-2025 |

Power Supply | 380V 50Hz 13KW |

Air Pressure | 0.5~0.7Mpa |

Max. Glass Size | 2000x2500mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Working Speed | 0~50m/min |

Max. Dispensing Pressure | ≤35Mpa |

Overall Dimension | 9500*2000*3000mm |

4.Packaging and Transportation

5.FAQ