Automatic Insulating Glass Argon Gas Filling Machine

Model No.: HH-CQX-2545

Brand: HH

Place of Origin:China

Max Glass Size: 2500*4500 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

1.Introduction of the product

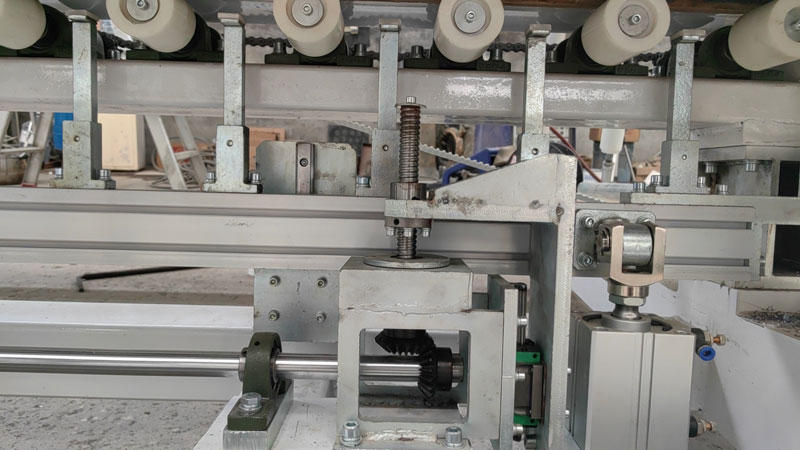

This production line adopts the most advanced IG manufacture technology and craft in the world. It is composed of input conveyor, washing and drying machine, inspecting conveyor, aluminum frame position, press machine and tilting table. The line can automatically process same edge glass (stepped glass) and double layers insulating glass. Automatic assembly and press in press machine makes it work with high efficiency.

2.Product advantages

(1)PLC control, touch screen human-machine interface, easy to operate.

(2)Can make double-layer, triple-layer, large and small glass, etc., automatically identify coated glass and LOW-E glass film.

(3)Imported glass suction cups and vacuum generators, better glass grabbing effect

(4)The protective plate is sprayed with plastic, with good performance and long service life

(5)The cleaning parts are made of stainless steel and resistor materials, and all electrical components are internationally renowned brands

(6)The pressing part can be widened to 450mm for easy maintenance. The pressing part adopts an open door type for easy maintenance.

3.Product parameters are as follows

Model | HH-CQX-2545 |

Power Supply | 380V 50Hz 45KW |

Air Pressure | 0.6~0.8Mpa |

Max. Glass Size | 2500×4500mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Conveying Speed | 0~50m/min |

Cleaning Speed | 2~12m/min |

Overall Dimension | 31000×2000×3600mm |

4.Packaging and Transportation

5.FAQ