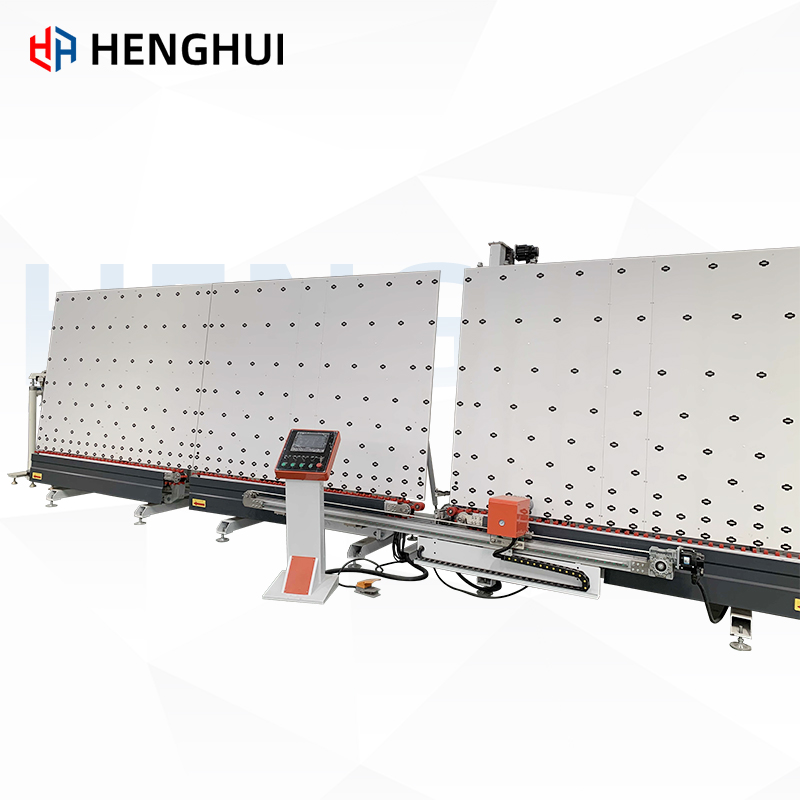

Vertical Insulating Triple-glass Sealant Coating Machine

Model No.: HH-FJX-2540

Brand: HH

Place of Origin:China

Max Glass Size: 2500*4000 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

1.Introduction of the product

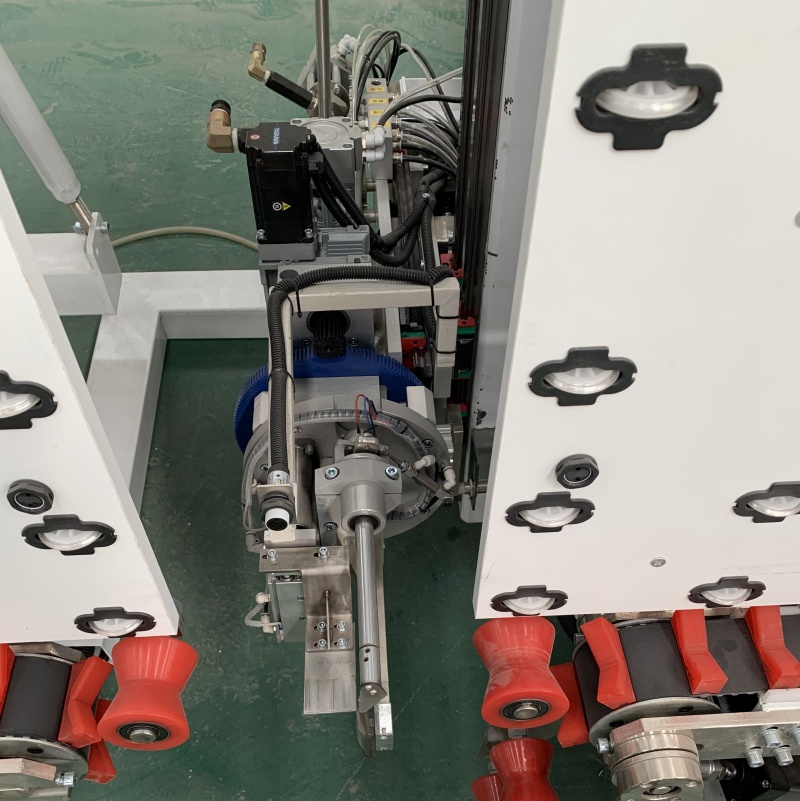

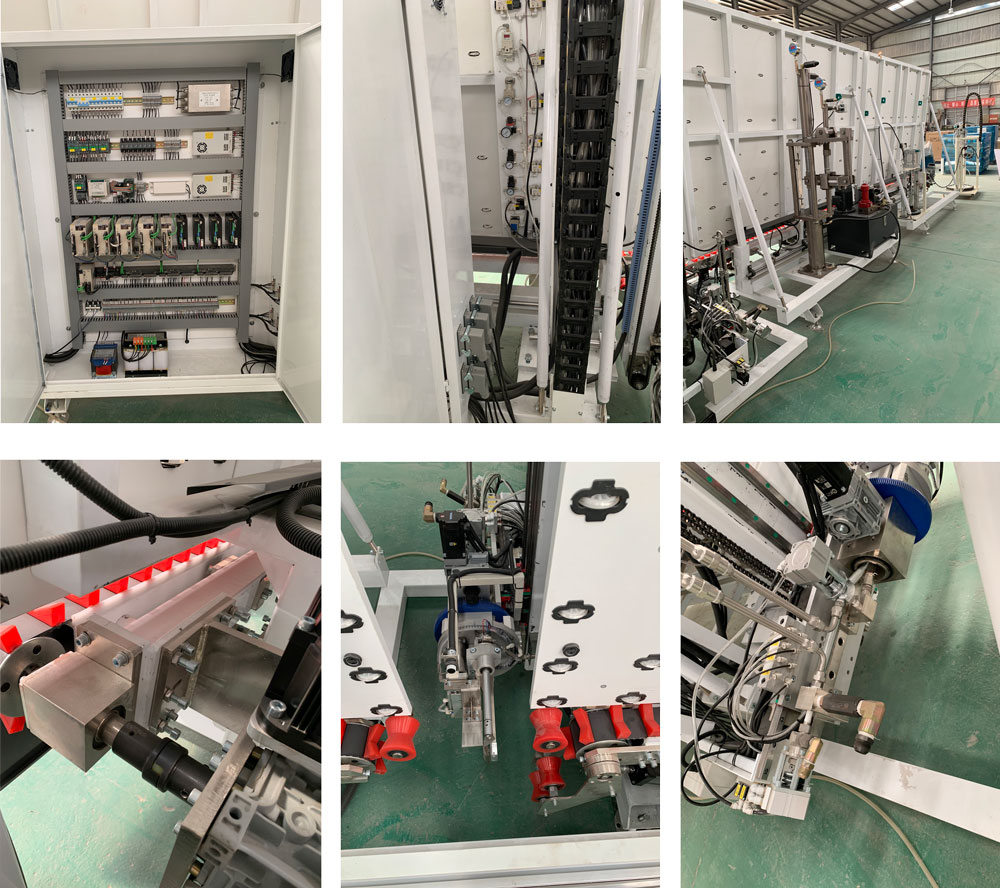

This production line is our company's high-end automatic sealing equipment, which is used for the final sealing of insulating glass production.It is composed of feeding section, discharging section, glue dispensing system, suction cup conveying system, glue supply system, pressurizing balance system, hydraulic system, electrical system, etc.

2.Product advantages

(1) Achieves seamless sealing of rectangular insulating glass of various sizes, ensuring high efficiency and stable quality.

(2) Offers two independent glue supply systems, with optional switch between two types of sealants.

(3) Enables pre-storage of glass in the third section for continuous equipment operation and improved production efficiency.

(4) Ensures full side coating without bubbles and seamless corners without manual trimming.

(5) Features a stable performance Yaskawa motion control system and servo control system, renowned globally.

(6) Employs an accurate synchronous belt transmission system for smooth, contamination-free glass handling.

(7) Includes dual sealant supply systems for quick switching and one-touch operation.

(8) Designed for triple glazing applications, accommodating diverse production needs.

3.Product parameters are as follows

Model | HH-FJX-2540 |

Power Supply | 380V 50Hz 13KW |

Air Pressure | 0.5~0.7Mpa |

Max. Glass Size | 2500×4000mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Working Speed | 0~50m/min |

Max. Dispensing Pressure | ≤35Mpa |

Overall Dimension | 12000×2000×3550mm |

4.Packaging and Transportation

5.FAQ