Automatic Gas Filling Insulating Glass Machine Production Line

Model No.: HH-CQX-2535

Brand: HH

Place of Origin:China

Glass Thickness: ≤50 mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

1.Introduction of the product

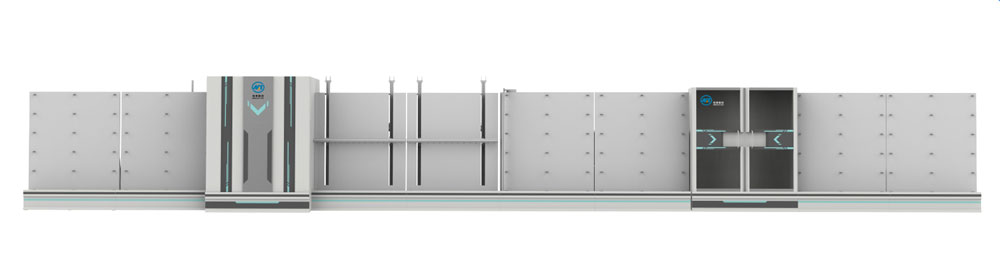

The Equipment can input the appropriate gas ratio value online, and all data can be displayed on the touch screen. During the inflation process, the touch screen can intuitively display the entire inflation process. How to display the argon filling ratio online on the touch screen is a key technology in the production of insulating glass.

2.Product advantages

(1) Comprehensive functionality with programs for both outside and inside assembly.

(2) Automated CNC Insulating Glass Production Line with automatic LOW-E identification.

(3) Controlled by Siemens PLC with a touch-sensitive screen for user interface.

(4) Utilizes imported vacuum generators and suction cups for optimal glass suction.

(5) Customizes production for step IG units and triple glass based on customer specifications.

(6) Fully automatic variable frequency speed adjustment across all distances, reducing idle time and enhancing production efficiency.

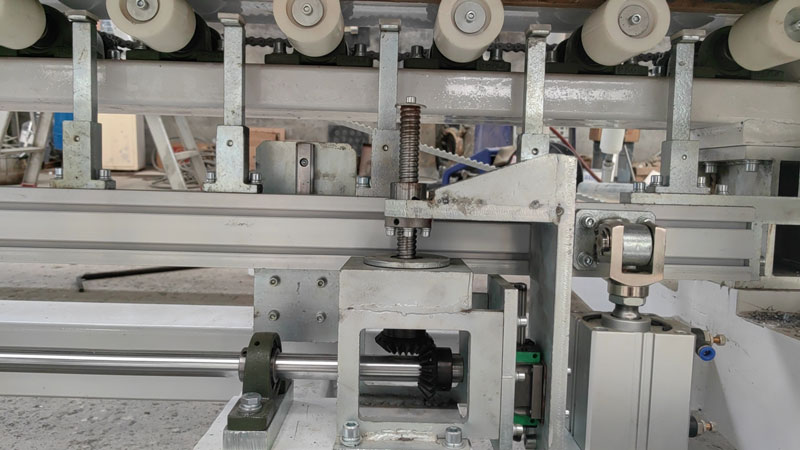

3.Product parameters are as follows

Model | HH-CQX-2535 |

Power Supply | 380V 50Hz 42KW |

Air Pressure | 0.6~0.8Mpa |

Max. Glass Size | 2500×3500mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~20mm |

Insulating Glass Thickness | ≤50mm |

Conveying Speed | 0~50m/min |

Cleaning Speed | 2~12m/min |

Overall Dimension | 28500×2000×3600mm |

4. Transportation and Packaging

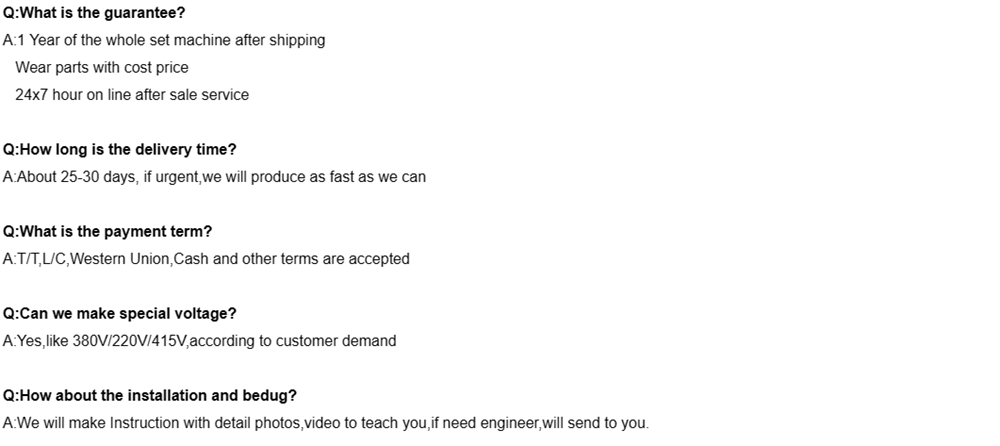

5.FAQ