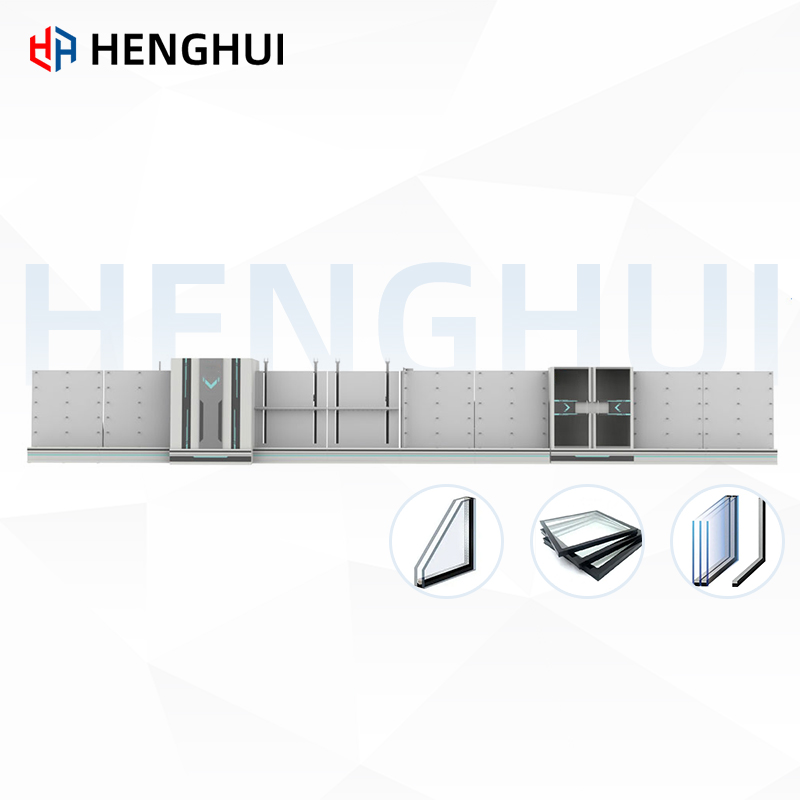

Triple Insulating Glass Making Machine Production Line

Model No.: HH-ZKX-2500

Brand: HH

Place of Origin:China

Glass Thickness: ≤80mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

1. Introduction of products

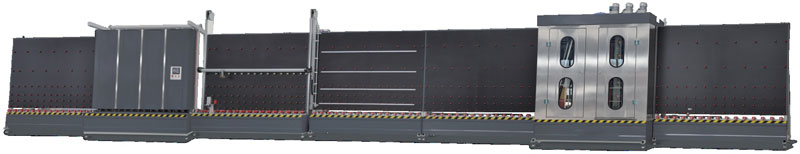

The Triple Insulating Glass Assembly Flat Press production line utilizes a vertical tilting mechanism for stable transmission, representing high-configured equipment for insulating glass processing. This production line handles Low-E insulating glass along with standard varieties, boasting high automation, efficiency, and ease of operation and maintenance. It stands as the optimal choice in current insulating glass manufacturing equipment.

2. Product advantages

(1)Capable of processing double-insulated glass (triple glass with double insulation), coating insulated glass, tempered insulated glass, and Low-E insulated glass etc.

(2)Featuring an inclined structure for stable conveying, PLC control, touchscreen display and switches, and automatic detection of key components.

(3)This equipment handles glass conveying, washing, drying, spacer positioning, automatic external assembly, flat pressing, insulated glass flipping, level adjustment, and discharge functions.

(4)Monitors its own operation to control equipment and prevent faults, ensuring product quality and enhancing safety.

(5)This production line is highly efficient, energy-saving, safe, easy to operate, space-saving, and aesthetically pleasing, making it the premier choice for insulated glass manufacturing.

3. Product parameters are as follows

Model | MT-ZKX-2500 |

Power Supply | 380V 50Hz 40KW |

Air Pressure | 0.6~0.8Mpa |

Max. Glass Size | 2450×3150mm |

Min. Glass Size | 260×450mm |

Glass Thickness | 3~12mm |

Insulating Glass Thickness | ≤80mm |

Conveying Speed | 0~50m/min |

Cleaning Speed | 2~12m/min |

Overall Dimension | 22800×2300×3550mm |

4.Packaging and Transportation

5.FAQ