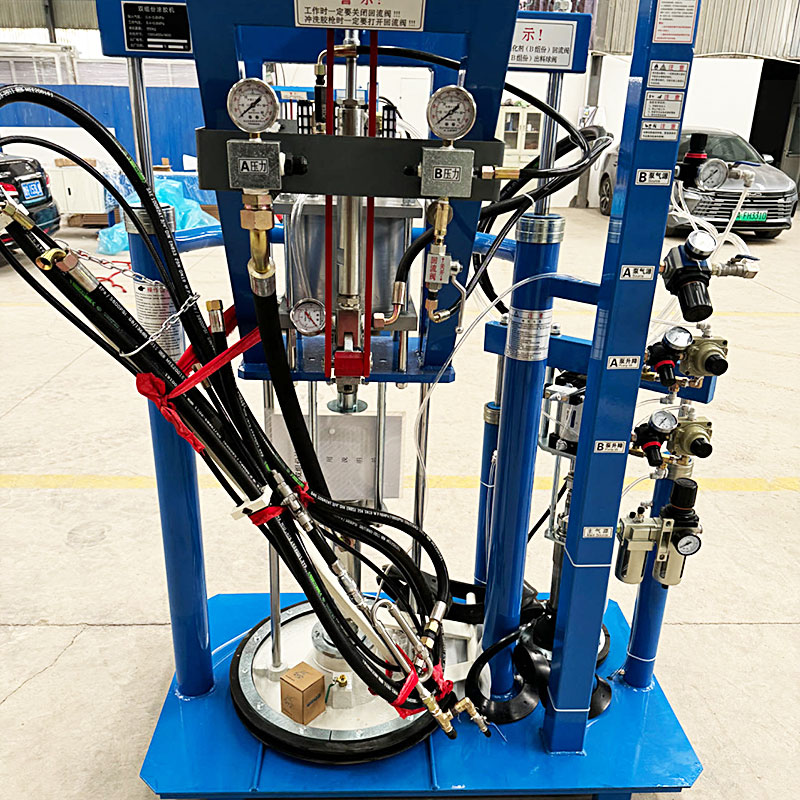

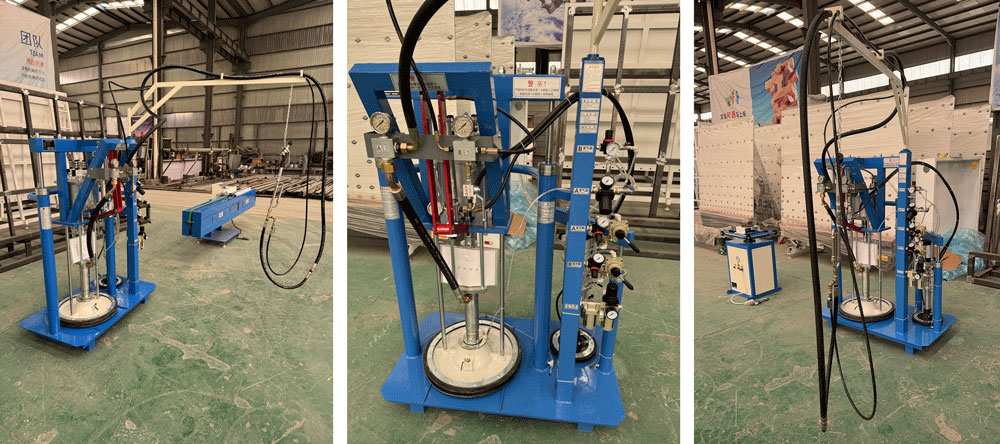

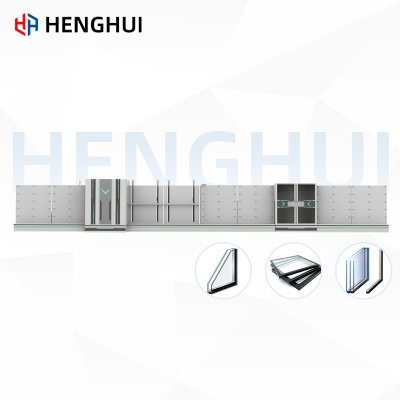

Insulated Glass Sealing Robot Two Component Coating Machine

Model No.: HH-TJJ-06

Brand:HH

Place of Origin: China,Shandong

Payment Type: LC, T/T

Incoterm: FOB, CFR, CIF, EXW

Min Order: 1 Set/Sets

Port: Qingdao, Shanghai, Tianjin

1.Introduction of products

HH-TJJ-06 collaborates with a rotating sealing machine in the production of hollow glass or curtain walls, effectively spraying a specialized sealant formed by combining A (organic synthesis) and B (curing agent) groups with adhesive. It meets the precise ratio demands of demanding plastic applications for efficient and high-quality operations in deep processing enterprises for doors, windows, and glass walls, ensuring a high pass rate on the production line.

2.Product advantage

(1)It combines components A and B seamlessly during the secondary sealing process.

(2)Known for its stable performance and rational structure, it excels in precise rubber proportioning.

(3)Tailored for efficient and high-quality simulation gluing operations in door, window, curtain wall, and glass processing sectors.

(4)Integrated gantry and triangular structures ensure enhanced stability, minimizing cantilever beam vibrations.

(5)The B pump features dual columns and seals on the pressure plate to prevent oxidation and leakage in the black component adhesive.

(6)Optimized pipeline design addresses speed limitations typical in similar products, ensuring superior performance.

3.Product parameters are as follows

Model | HH-TJJ-06 |

Mixing Ratio | 6:1~14:1 |

Material Bucket | 55Gal(200L) |

Curing Agent Drum | 5Gal(20L) |

Air Pressure | 0.5~0.8Mpa |

Max. Air Consumption | 0.8M /min |

Max. Dispensing Pressure | 25Mpa |

Output | 4~10L/min |

Weight | 500kg |

Overall Dimension | 1350×850×1850mm |

4.Transportation and Packaging

5.FAQ