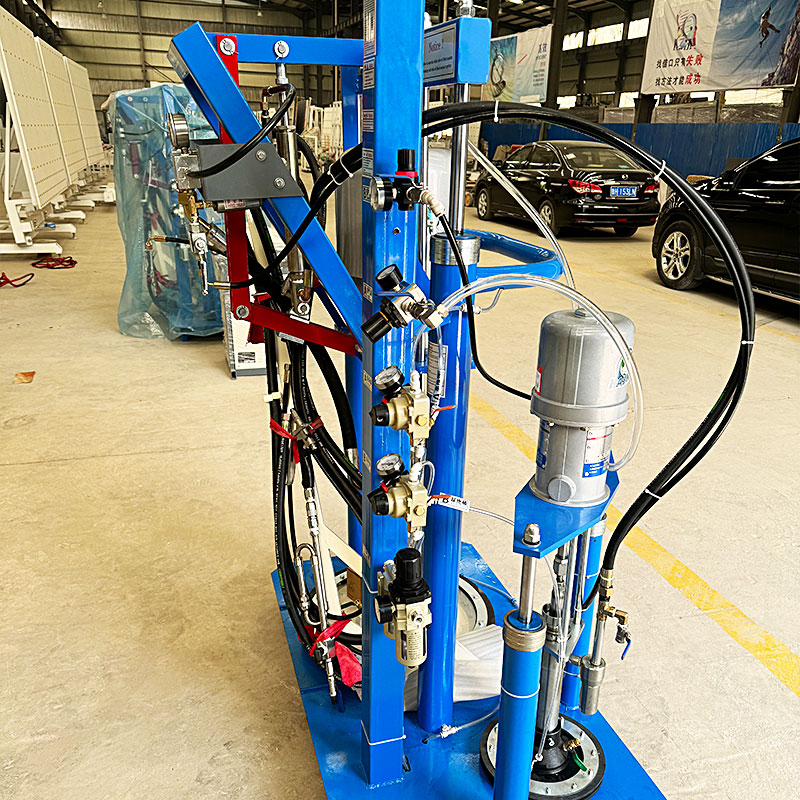

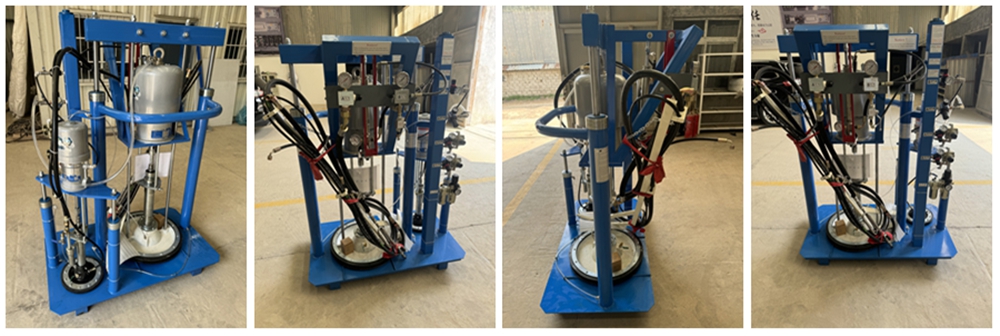

Pneumatic Two Component Sealant Extruder Machine

Model No.: HH-TJJ-02

Brand:HH

Place of Origin: China,Shandong

Payment Type: LC, T/T

Incoterm: FOB, CFR, CIF, EXW

Min Order: 1 Set/Sets

Port: Qingdao, Shanghai, Tianjin

1.Introduction of products

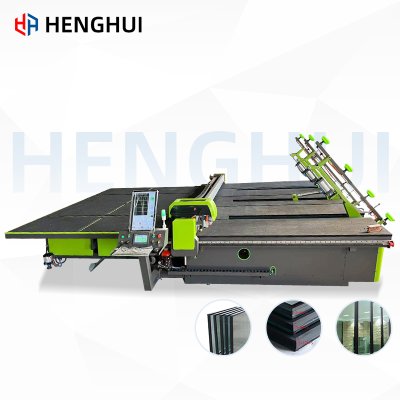

This machine working with rotated sealing machine on production of hollow glass or curtain wall to spray a special sealed in the realization of A(organic synthesis) and B(curing agent) groups were mixed with a glue to complete. Particularly suited to the requirements of the ratio of precision plastic kind of harsh for doors and windows and walls of glass deep processing enterprises efficient, high-quality, high pass rate of the production line operating needs.

2.Product advantage

(1)Achieve the mixing and gluing of components A and B in the secondary seal at one time.

(2)This machine has stable performance and reasonable structure, and is especially suitable for rubber types that require precise proportioning.

(3)It is suitable for high-efficiency, high-quality, and high-qualification simulated gluing operations in door, window, curtain wall, and glass deep processing enterprises.

(4)Take overall action to increase the gantry and triangle to form a stable structure to overcome the shaking of the cantilever beam during operation.

(5)The B pump adopts double columns and double seals on the pressure plate, which completely solves the problem of easy oxidation and leakage of black component glue.

(6)Optimize the pipeline design and solve the problem of slow speed of similar products.

3.Product parameters are as follows

Model | HH-TJJ-02 |

Mixing Ratio | 6:1~14:1 |

Material Bucket | 55Gal(200L) |

Curing Agent Drum | 5Gal(20L) |

Air Pressure | 0.5~0.8Mpa |

Max. Air Consumption | 0.8M /min |

Max. Dispensing Pressure | 25Mpa |

Output | 4~10L/min |

Weight | 500kg |

Overall Dimension | 1200×950×1750mm |

4.Transportation and Packaging

5.FAQ