End-milling Machine for Aluminum Door

Model No.: LXD-250B

Brand: HH

Place of Origin:China

Dimension Size: 2700×1000×1750mm

Payment Type:LC,T/T

Incoterm:FOB,CFR,CIF,EXW

Min Order:1 Set/Sets

Port: Qingdao,Shanghai,Tianjin

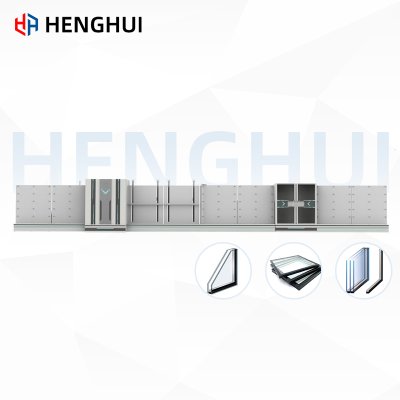

1. Introduction of products

This machine is designed for milling the end faces of transom profiles in thermal break aluminum doors and windows. It can handle 6 to 10 aluminum profiles simultaneously, ensuring high production efficiency. The cutter is adjustable vertically and horizontally to accommodate various shapes and sizes of aluminum profiles. Utilizing a hydraulic damping cylinder for tool feed ensures stable operation. With a larger tool diameter, it enhances machining surface quality for superior results.

2. Product advantages

(1)This machine is used for aluminum profile end face processing and suitable for various profiles.

(2)It can process multi-piece profiles at one time,with high efficiency. (3)Convenient tool adjustment to meet different processing requirements. (4)No necessory to order tools when processing various profiles,saving cost and time.

(5)Large tool diameter,high milling speed and good processing result. (6)According to user's requirement,this machine is installed safety cover which can keep safe operation.

(7)Adopt electrical motor protect device to improve the safety.

(8)Adopt lead screw feeding device,more smoothly.

3. Product parameters are as follows

Model | LXD-250B |

Power Supply | 380V 50Hz |

Input power | 8.8KW |

Air pressure | 0.5~0.8MPa |

Air consumption | 150L/min |

Main shaft diameter | φ32mm |

Milling cutter diameter | φ250mm |

Motor speed | 2800r/min |

Dimension | 2700×1000×1750mm |

Weight(about) | 800Kg |

4. Transportation and Packaging

5. FAQ